Automated Gluing vs Manual Application: Which One Wins?

Exploring the most up to date Developments in Woodworking Machinery for Boosted Workmanship

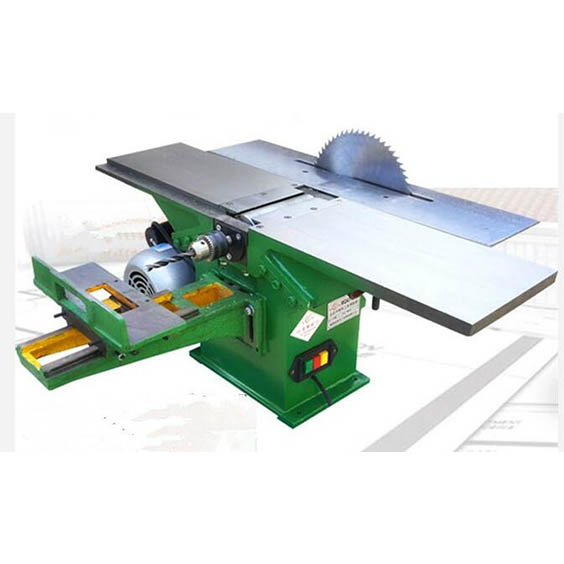

The woodworking industry is undergoing considerable improvement as a result of recent improvements in equipment. Developments such as clever saws, CNC devices, and laser cutters are redefining accuracy and efficiency (Rotary Claming System). These tools not only enhance workmanship however also promote safety and tidiness in the work space. As technology integrates with conventional methods, a brand-new degree of creative thinking emerges. The ramifications of these growths raise questions regarding the future of woodworking and the capacity for also greater technologies in advance

Smart Saws: Precision Reducing for every single Wood Type

Over the last few years, various technologies in woodworking machinery have actually arised, with smart saws leading the way in precision cutting for different wood kinds. These advanced devices use digital innovation to enhance precision and effectiveness, enabling woodworkers to accomplish accurate cuts with very little effort. Geared up with sensing units and automated systems, clever saws can automatically adjust settings based on the type and density of the timber, making certain peak efficiency for every project.

CNC Machines: Bringing Intricate Styles to Life

CNC makers stand for a significant advancement in woodworking innovation, making it possible for artisans to bring detailed styles to life with exceptional precision. These computer-controlled devices make use of advanced software to analyze electronic styles and carry out complicated cuts and carvings, minimizing human error and making the most of performance. With the capability to work with numerous materials, consisting of compounds, softwoods, and woods, CNC machines cater to varied woodworking jobs, from furnishings making to elaborate cabinets.

Craftsmen can develop comprehensive patterns and forms that would certainly be almost impossible or labor-intensive to attain with standard tools. The versatility of CNC machines additionally enables rapid prototyping, making it possible for designers to evaluate and improve their ideas promptly. Because of this, these equipments not only boost craftsmanship yet also broaden the innovative opportunities within the woodworking industry. By integrating precision and modern technology, CNC makers have actually transformed the means artisans approach their craft, establishing new standards for quality and layout.

Laser Cutters: Enhancing Information and Efficiency

While several woodworking devices improve performance, laser cutters stick out for their capability to deliver extraordinary information and effectiveness. These innovative makers make use of concentrated laser light beams to puncture wood with unmatched precision, allowing craftsmens to develop complex designs that conventional techniques can not accomplish. The rate at which laser cutters run greatly decreases production time, allowing artisans to take on even more tasks without sacrificing quality.

Laser cutters likewise use versatility, accommodating various materials past wood, such as composites and polymers. This flexibility permits businesses to diversify their offerings and attract click here for more a broader customers - Lumber Stacker. In addition, laser technology reduces waste by making cleaner cuts, which is both cost-efficient and environmentally pleasant

As woodworking continues to develop, the combination of laser cutters stands for a significant advancement, encouraging craftsmen to push the borders of creativity and performance in their work. This development marks a crucial change in the woodworking market, enhancing both artistry and performance.

Dust Collection Solutions: Keeping a Tidy Workspace

As woodworking tasks generate substantial quantities of dirt and particles, reliable dust collection systems play a vital function in preserving a risk-free and tidy work space. These systems are made to capture and eliminate particle issue created during reducing, sanding, and milling processes, thus enhancing air top quality and reducing the risk of respiratory problems for craftsmen.

Modern dirt collection systems make use of advanced innovation, consisting of cyclonic separation and high-efficiency filters, to maximize dirt extraction performance. Lots of systems can be integrated with existing machinery, enabling smooth operation and minimizing arrangement time.

Furthermore, mobile dirt enthusiasts supply adaptability for varying project dimensions and areas, making sure that woodworkers can preserve tidiness despite workspace restraints. Applying a robust dust collection system not only boosts the overall woodworking experience however likewise extends the life of tools and machinery by protecting against dust accumulation. As a result, buying quality dirt collection is essential for any kind of severe woodworker.

Digital Layout Software: Improving the Creative Refine

Many software application options integrate seamlessly with CNC devices, enabling for computerized manufacturing based on digital designs - Automated Gluing. This read the article fusion of technology and craftsmanship not only accelerates the construction process yet additionally equips woodworkers to check out ingenious layouts without the restraints of typical strategies. Eventually, digital layout software program is reshaping woodworking, cultivating a brand-new era where imagination and technology exist together sympathetically

Regularly Asked Inquiries

What Are the Upkeep Demands for Modern Woodworking Equipment?

Modern woodworking machinery calls for normal cleansing, lubrication of moving components, evaluation for wear and tear, tightening up of loose elements, and regular calibration to guarantee peak performance and longevity, adding to total effectiveness and security during procedures.

How Do I Select the Right Device for My Workshop Dimension?

To select the best device for a workshop dimension, one ought to examine offered room, take into consideration the machine's impact, examine power demands, and prioritize multifunctional tools for performance, guaranteeing compatibility with the designated woodworking tasks.

Exist Safety And Security Functions in New Woodworking Machines?

Several new woodworking devices integrate sophisticated safety and security functions, such as automatic shut-off systems, blade guards, and emergency quit switches. These improvements aim to protect customers and minimize crashes, promoting a much safer working atmosphere for craftsmen.

What Is the Typical Life-span of Woodworking Equipment?

The typical life expectancy of woodworking equipment typically ranges from 10 to twenty years, relying on usage, upkeep, and the top quality of the equipment. Routine maintenance can significantly prolong its operational performance and long life.

Exactly How Can I Financing the Purchase of Woodworking Tools?

Funding woodworking equipment can be achieved with numerous means, including individual loans, tools financing choices, leasing arrangements, or making use of little service lendings. Assessing one's budget plan and looking into funding resources is essential for notified decision-making.

As a result, these equipments not just improve craftsmanship however also broaden the imaginative possibilities within the woodworking sector. Carrying out a robust dirt collection system not only boosts the general woodworking experience but also lengthens More Bonuses the life of devices and machinery by protecting against dust accumulation. In parallel, electronic design software application has actually emerged as a crucial tool in the woodworking industry, markedly simplifying the innovative process. Several brand-new woodworking makers include innovative security attributes, such as automatic shut-off systems, blade guards, and emergency quit switches. The ordinary life-span of woodworking equipment normally ranges from 10 to 20 years, depending on use, maintenance, and the top quality of the machine.